Building and renovating in an energy-efficient and resource-efficient way

Ceramic Roadmap

TO 2050

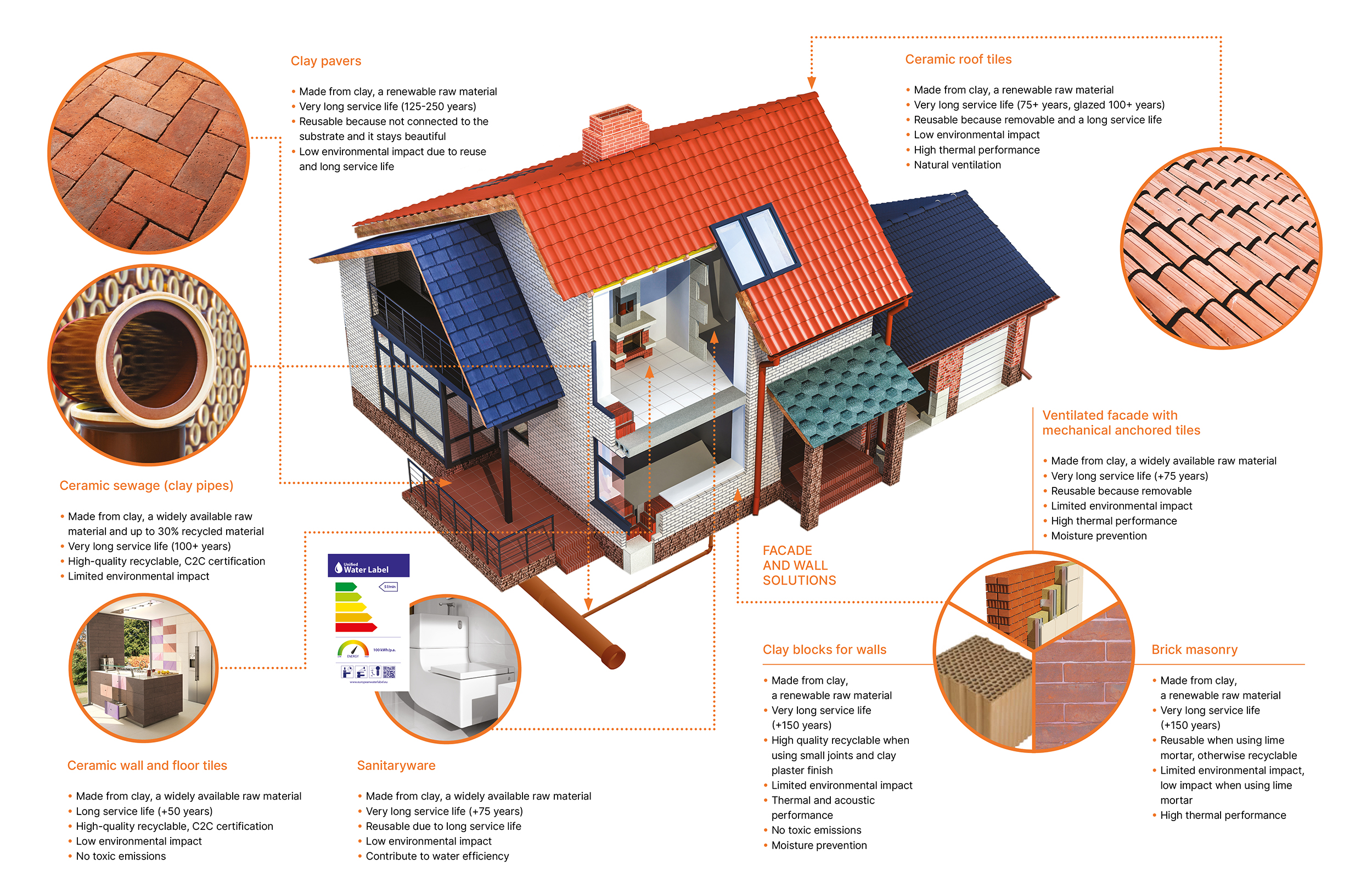

The energy-saving potential, durability, and reusable qualities of ceramic construction materials (clay bricks, blocks, roof tiles, pavers, expanded clay, wall and floor tiles and sanitaryware) have been known for centuries. With a renewed focus on energy efficiency and circularity, the European ceramic industry will be central to reducing energy use and construction waste.

Supporting the Renovation Wave

Renovation of our existing building stock and focusing on near zero energy building are paramount to meeting Europe’s decarbonisation objectives.

Ceramic construction materials are durable, affordable and provide comfortable, energy-efficient, safe and healthy homes to millions of people in Europe.

Ceramic construction materials provide high levels of safety in case of fire or flood. They also ensure a high indoor air quality, as no toxic emissions emanate from the building fabric into the internal environment.

Ceramic wall and roof systems not only increase comfort but reduce heating and cooling costs and emissions.

Innovative ceramic sanitary appliances contribute to water and energy efficiency, notably in the context of voluntary smart tools promoted by the industry such as the Unified Water Label.

Ceramic construction materials will be pivotal to Europe’s new near-zero energy building stock as well as its Renovation Wave.

Collectively, buildings in the EU are responsible for 40% of our energy consumption and 36% of greenhouse gas emissions.

Clay brick cavity walls and monolithic clay block walls with integrated insulation can normally reach any required insulation value by varying the insulation thickness. They also offer a maintenance-free solution for a lifetime.

Ventilated facades create an air chamber between the cladding material and the structural surface of the building. Such systems can easily be applied in renovation on any material. A building with a ventilated façade system can be in some cases 35% more energy efficient. Other benefits of ventilated facades include the reduction of dampness on walls, deterring the formation of thermal bridges and providing a comfortable indoor climate by preventing heat from escaping in winter and entering in summer, and improved sound absorption.

Doing more with less

Houses with pitched roofs are more space-efficient than those with flat roofs, offering more floor space for the same footprint.

Furthermore, clay brick walls can store solar and internal heat gains and radiate the energy out when it is needed. Moreover, bricks are a cost-effective solution to treat thermal bridges.

Ceramic roof tiles are among the most energy-efficient types of material. They have a high thermal emittance, are recyclable and last for decades. They also allow for natural ventilation, creating a thermal barrier that prevents heat loss through the roof.

Keeping it cool

Energy efficiency is not only about keeping heat in. In warmer, southern European climates, keeping heat out is equally important. With air conditioning becoming ever more popular, ceramic roof tiles can help to keep heat out and cool air in, thus reducing demand for air conditioning systems.

- Thermal emittance

Instead of absorbing heat into our buildings, ceramic roof tiles and ventilated facades reflect heat back into the air. - Regulate humidity

Moreover, bricks and ventilated facades regulate moisture and provide a comfortable indoor climate and dry walls. - Solar reflectance

Lighter-coloured ceramics help reflect the sun’s rays during the day, allowing buildings to stay cool naturally. - Individual tile installation

Since in some regions roof tiles are installed individually rather than in an overlapping sheet style, they allow for more natural ventilation, creating an airspace that forms a thermal barrier.

Bricks and roof tiles are affordable, locally produced materials that are central to both new energy-efficient buildings and renovating our existing building stock. Reducing emissions using sustainable ceramics will go hand in hand with providing local employment.

Deconstruction & circularity: going back to our roots

Abandoned buildings have been used as a source of materials for new construction for thousands of years. Bricks were cleaned and reused, and tiles recycled: until the early 20th century, demolition crews took care to keep construction materials intact. But labour costs, regulation, building standards and perception have largely ended this sustainable practice.

Durability

For many people in Europe, buying a home is a once-in-a-lifetime decision and an investment for the future. The durability and the quality of the materials is thus essential. In addition, the lengthening of the average duration of mortgage loans (more often 30 years than 20 years) requires choosing a sustainable building that will limit the need for maintenance and preserve the value of the property.

Ceramic construction products are affordable, resource-efficient and have high durability, requiring little or no maintenance. A brick house has an average life span of more than 150 years, as do clay pipes and buildings containing expanded clay. Sanitaryware appliances and ceramic tiles for flooring and walls can have a life span of up to 50 years, which compares favourably to alternative materials.

Reuse

Increased urbanisation and the depletion

of natural resources are making the demolition / reconstruction model increasingly unsustainable. Ceramic construction materials have been reused for centuries, and now contribute to innovative thinking about how we can give new life to construction materials.

Existing buildings can be reused in situ, or dismantled and rebuilt in a different location. For example, industrial buildings can be converted into offices or housing. Because of their durability, brick buildings are perfectly suited to these types of conversions, which not only reduces the need for natural resources, but preserves the heritage of our built environment.

Reusing existing buildings avoids their demolition and preserves resources otherwise needed to construct a new building. In addition, the reuse of existing buildings can preserve their cultural and historical value. In urban areas, this type of adaptive reuse is an effective way to reduce urban sprawl and the associated environmental impact.

In many cases, ceramic construction materials can be reused:

- Walls using facing bricks in dry stack systems or bricks stacked with lime mortar can be easily dismantled and the bricks reused. Brick manufacturers have also developed hanging systems where bricks or brick slips glued on panels are detachably connected to an underlying frame, to be easily reused.

- Roof tiles are easy to disassemble, have a very long service life and can be reused after deconstruction.

- In addition to the traditional recycling applications, new floor tiles are developed that do not require glue or cement and are thus removable and reusable.

- Ceramic pavers are frequently reused, which increases their economic value. Clay pavers have a reuse percentage of at least 90% and an average lifespan of 125 years.

Recycling

When ceramic construction materials cannot be reused, they can be recycled for a range of purposes. Secondary raw materials (being waste in other industries) are also used in the manufacturing of ceramics.

Closed loop recycling

- The use of internal production residues from the production of bricks and wall and floor tiles as a substitute for raw materials is common practice across Europe.

- Ceramic clay powder that can be used as substitute to Portland cement, and crushed brickwork, can be used also in the production of cement clinker.

- Other organic sources, such as sawdust, rice husks or sunflower seed shells are used in the clay block production process to improve insulation properties.

Open loop recycling

- Many ceramic construction products can be crushed to a defined grain size distribution and used as a lightweight aggregate in the production of concrete blocks.

- Several ceramic construction products that have reached the end of their useful life are commonly recycled: for example, in backfilling pits and quarries, as a water-bound cover layer, as aggregates for substructure, as a surface layer in road construction, as vegetation substrate or as roofing substrates for green roofs.

- Sanitaryware can be recycled.

- Recycled wall and floor tiles can be used to stabilise the ground when constructing new roads.

Policy recommendations

A holistic and integrated approach to building renovation

Cerame-Unie supports the objectives of the Renovation Wave. A holistic and integrated approach is recommended to building renovation to stimulate the whole construction sector. Building renovation is not just about energy efficiency; the efficiency of the water load used should not be neglected. In this context, Cerame-Unie supports smart tools such as the Unified Water Label, which offers clear and easy-to-understand information on water and energy use of bathroom products.

Promoting both renovation and new construction

Both renovation and new construction should be promoted. Mandatory examinations should be carried out to determine whether deep renovation (purely energetic renovation) or demolition and subsequent rebuilding is ecologically and economically more reasonable. It is sometimes more efficient to entirely rebuild a building than to renovate an old one. In addition, a new building can be more energy-efficient, and will be better adapted to new social needs as well as to recent urban developments around it. Therefore, renovation and new construction should receive the same fiscal and financial incentives.

Sufficient financial support

Sufficient financial support both for research and innovation and for investments (CAPEX) and to mitigate higher running operational costs (OPEX). The industry should also have access to Carbon Contracts for Difference.

Supporting holistic life cycle assessment schemes

Ceramic construction products manufacturers support holistic life cycle assessment schemes for buildings and for many years have provided the necessary environmental and sustainability product data via the use of voluntary environmental product declarations (EPDs). In this context, Cerame-Unie supports the work of CEN/TC 350 and welcomes European initiatives such as Level(s).

Supporting the New European Bauhaus initiative

The European ceramic industry welcomes and supports the New European Bauhaus initiative, which aims at shaping future ways of living according to key principles of sustainability, inclusion and quality of experience, thus contributing to the well-being of citizens.

Implementing the Construction Products Regulation

The Construction Products Regulation (CPR) provides a common technical language to assess the performance of construction products. Cerame-Unie believes that the revision of the CPR should bring as few legal changes as possible, to avoid confusion in the market and additional costs to manufacturers. In the short term, solutions should be found to the most urgent problems related to the implementation of the CPR, such as the backlog in the citation of harmonised product standards in the Official Journal of the European Union, to avoid legal uncertainty and instability for the industry.